Airflow Dyeing Machine

The New Age Airflow Dyeing Machine works on the principle of the aerodynamic dyeing system, i.e. Dyeing by mixing the dyestuffs with airflow. When the fabric transport takes place by means of airflow, the fabric can run with out liquor, thus consuming the minimum quantity of dye liquor. The airflow mixes with the dyestuffs and subsequentiy the liquor is atomized and eveniy sprayed onto the surface of the fabric. This is to ensure a high penetration of the fabric and consequentiy achieve the excellent dyeing effect.

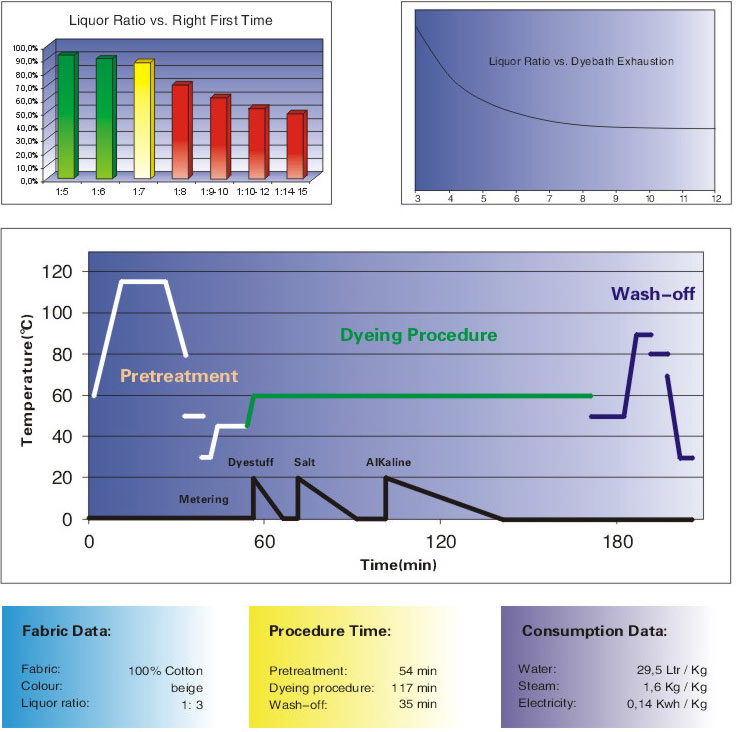

Extreme low and constant liquor ratio

Extreme low and constant liquor ratio

- Liquor ratio can be as low as 1:1.5 and 1:3 depending on the types of fabric.

- Constant liquor ratio even with fabric loading from 50% to 100%.

Best fabric quality

- Smooth fabric running on teflon rods storage chamber with no entanglement.

- Low tension of fabric by air suction support transportation

- Even distribution of dye liquor by means of air spray with new patented design nozzle.

- High fabric speed (up to 700m/min), short circulation time and best displacement.

Shower rinsing system

- Fabric rinsing by using shower instead of conventional water bath, saves huge amount of water and shortens the rinsing time.

Hot drain

- Hot drain with integrated heat recovery (patent pending).

- Allows to drain the bath even at 130 oC

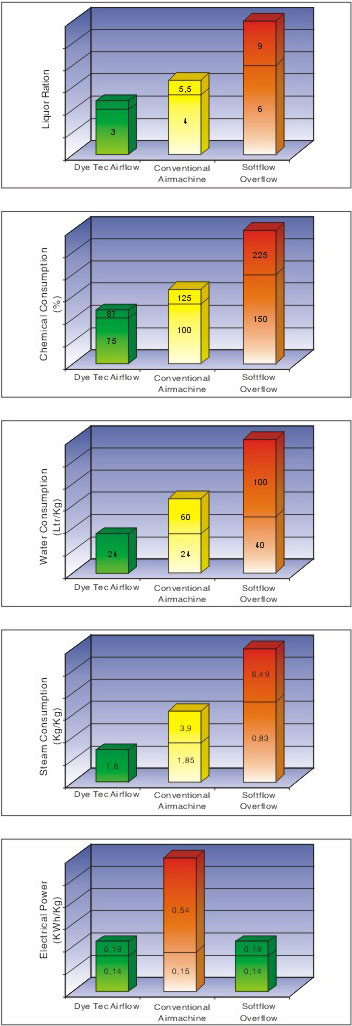

Tremendous savings

- Extreme low liquor ratio saves a lot of dyestuff, chemical, water and energy, thus saving enormous operation cost.

- New designed nozzle system can save tremendous energy with even better displacement of fabric.

Environmental friendly

- Investing in a dyeing machine means to take up a big responsibility not only for your company, but also for the environment.

- The low liquor ratio allows saving of chemicals, salt, steam and water up to 60-70%. And what is not brought into a dyeing machine will also not harm the environment. Thus you save money and hold the environment harmless.

- Thanks to the constant research and development, the Dye Tec Airflow has a very low electrical power consumption substantially lower than that of many other dyeing machines.

Options

-

Hot water Module

to serve water in time with right temperature -

Hot drain

to drain the bath even at 135 oC -

Spectra dyeing

astonishing results of controlled random dyeing (Tye' DYE, Batik) -

PH measuring

to control important dyebath parameters -

Add valves

up to 4drain and / or fill valves

Machine Functions

Autotrim:

Just add the trims, collars and cuffs to the fabric you want to dye. The New Age Dye Tec Airflow takes care of it and adjusts all parameters to get an optimem result.

Autopower:

With the New Age Dye Tec Airflow the electrical power consumption is always kept to the lowest possible level.

Autonozzle:

The New Age Dye Tec Airflow nozzle has especially heen designed for the treatment of cotton knitwear. Its shape ensures an optimum fabric transportation enhancing the quality of the precessing fabric.

AutoLR:

With the New Age Dye Tec Airflow liquor ration is always kept at its lowest level.

Autoleveliness:

The New Age Dye Tec Airflow controller configurates the best parameters to achieve the optimum dyeing result. Operation is most easily done.

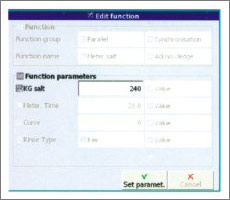

Autosalt:

Metering of either dry or wet salt is no big issue with a lot of question marks any longer. Just key in the amount of salt and the metering time and the New Age Dye Tec Airflow is doing the job.

Autoliq:

Just key in the time and the metering curve you want to have. Here again the New Age Dye Tec Airflowis calculating everything on its own.

Autorinse:

The New Age Dye Tec Airflow adjusts all parameters for an optimum rinsing result. Lowest possible water consuption and best rinsing effects are quaranteed.

Autodata:

The controller of the New Age Dye Tec Airflow shows the consumption of water and electricity for every batch, which serves as an excellent base for cost calculations.

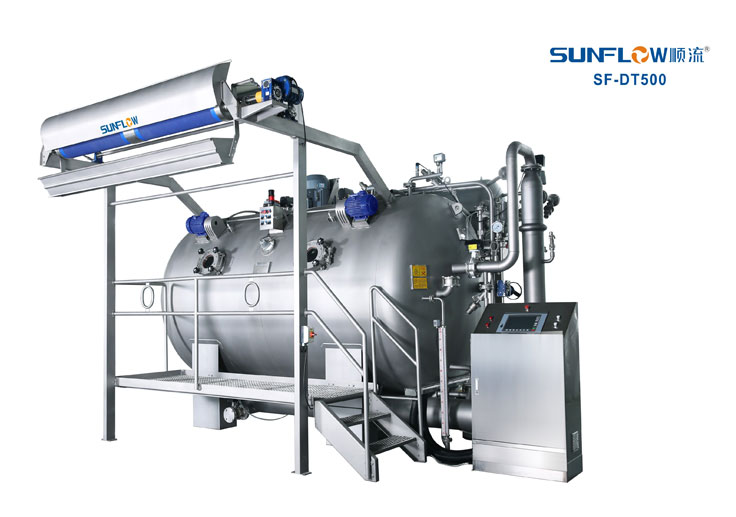

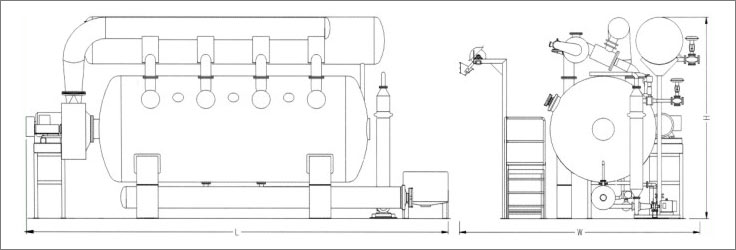

Dimensions

| Model | Nominal Capacity (Kg) | Dimensions (mm) | ||||||

| L | W | H | ||||||

| Kg | lb | mm | in | mm | in | mm | in | |

| S-DT 250 | 250 | 550 | 4760 | 187 | 4980 | 196 | 4300 | 169 |

| S-DT 500 | 500 | 1100 | 6170 | 242 | 4980 | 196 | 4300 | 169 |

| S-DT 750 | 750 | 1650 | 7600 | 299 | 4980 | 196 | 4300 | 169 |

| S-DT 1000 | 1000 | 2200 | 9000 | 354 | 4980 | 196 | 4300 | 169 |

| S-DT 1500 | 1500 | 3300 | 11850 | 466 | 4980 | 196 | 4300 | 169 |

| S-DT 2000 | 2000 | 4400 | 14660 | 577 | 4980 | 196 | 4300 | 169 |

| S-DTL 250 | 250 | 550 | 4420 | 174 | 3420 | 135 | 4230 | 167 |

| S-DTL 500 | 500 | 1100 | 5500 | 217 | 3420 | 135 | 4230 | 167 |

| S-DTL 750 | 750 | 1650 | 6680 | 263 | 3420 | 135 | 4230 | 167 |

| S-DTL 1000 | 1000 | 2200 | 7860 | 310 | 3420 | 135 | 4230 | 167 |

| S-DTL 1500 | 1500 | 3300 | 10220 | 402 | 3420 | 135 | 4230 | 167 |

| S-DTL 2000 | 2000 | 4400 | 12570 | 495 | 3420 | 135 | 4230 | 167 |

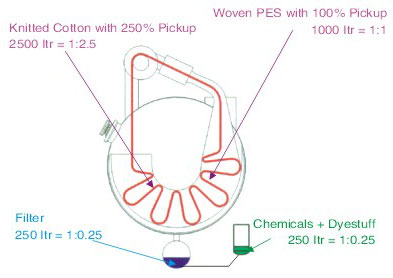

Liquor Ratio

| 1000Kg New Age Airflow | Full Loading | 50% Loading | |

| Types of Fabric | Woven PES | Knitted Cotton | Knitted Cotton |

| Fabric Pick up | 1000 ltr | 2500 ltr | 1250 ltr |

| Filter Volume | 250 ltr | 250 ltr | 250 ltr |

| Starting LR | 1250 ltr | 2750 ltr | 1500 ltr |

| Chemicals + Dyestuffs | 250 ltr | 250 ltr | 150 ltr |

| Final LR |

1500 ltr 1:1.5 |

3000 ltr 1:3 |

1650 ltr 1:3.3 |